What is batch fermentation?

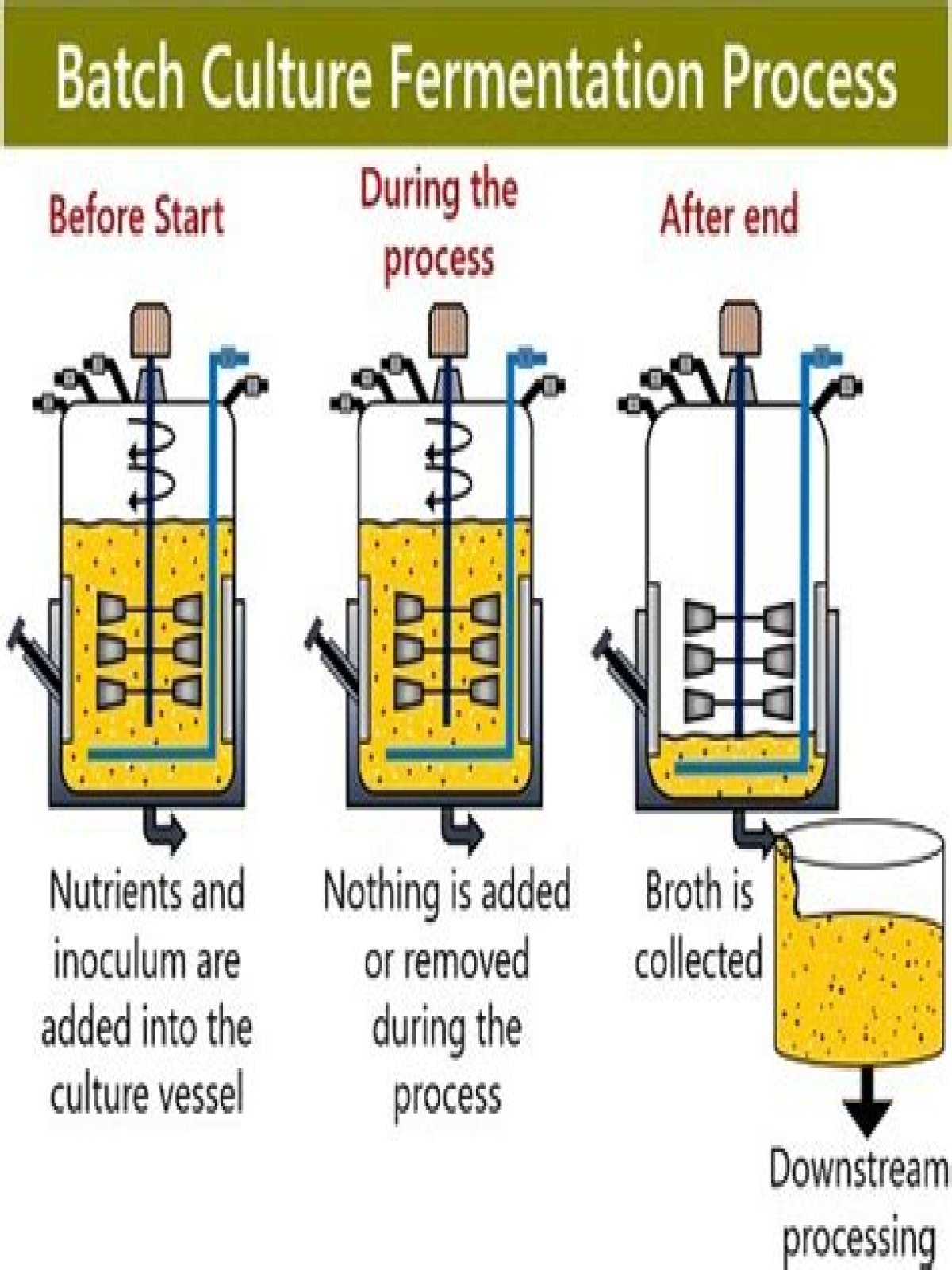

1 Batch fermentation. Batch fermentation is a process where all the substrate and nutrients are added at zero time or soon after inoculation takes place, and the vessel is allowed under a controlled environment to proceed until maximum end product concentration is achieved.

What is called fed-batch culture?

Fed-batch culture is, in the broadest sense, defined as an operational technique in biotechnological processes where one or more nutrients (substrates) are fed (supplied) to the bioreactor during cultivation and in which the product(s) remain in the bioreactor until the end of the run.

What is continuous fermentation?

Continuous Fermentation is a method of converting wort into beer in a continuous process, whereby wort is fed into one end of the process and beer is discharged at the other without recourse to holding the beer in a static holding vessel (batch fermentation).

What is batch and fed-batch?

Batch, where no extra feeding is used from beginning to end of the process. Fed-batch, where feeding with substrate and supplements can extend the duration of culture for higher cell densities or switch metabolism to produce e.g. a recombinant protein.

What is the difference between fed-batch and batch fermentation?

In batch fermentation, all the medium components are placed in the reactor at the start of cultivation. A fed-batch culture is a modification to batch fermentation in which nutrients are systematically added. The nutrients are all supplied at the beginning of cultivation, without further additions later on.

What is the advantage of batch fermentation?

Batch fermentation has the advantages of low investment costs, simple control and operations, and easy-to-maintain complete sterilization. However, seed culture is needed for each new batch. Bioethanol from corn in the USA is almost entirely produced using batch fermentation.

What is the difference between fed-batch and perfusion?

Fed-batch reactions typically last 10-14 days, while perfusion processes run for 30-60 days or longer. Perfusion processes also can offer significantly higher productivities in grams/L of bioreactor working volume per day, enabling the use of smaller, single-use bioreactors and reducing capital expenditures.

What is characteristic of fed-batch culture?

Through the manipulation of the feed rates of the medium containing the substrate and nutrients, the fed-batch operation allows regulation of the concentration of key substances that control the cell growth and/or product formation rate.

Is batch or continuous fermentation faster?

In batch fermentation, turnover rate is low. In continuous fermentation, turnover rate is high. In batch fermentation, nutrients are used by the microorganisms in slower rate. In continuous fermentation, nutrients are utilized rapidly by the microorganisms.

Why does fed-batch ferment?

Fed-batch fermentation is therefore very useful for bioprocesses that aim for high biomass density or high product yield when the desired product is positively correlated with microbial growth. The growth rate can be controlled by the substrate concentration to avoid catabolite repression.

What are the disadvantages of batch culture?

The major disadvantage of batch cultivation is its low productivity due to its high downtime (nonproduction time which is used for cleaning, sterilization, and startup of another batch cultivation) during two batch cultivations.

¿Qué es un reactor tipo batch?

El reactor tipo Batch es un reactor donde no existe flujo de entrada ni de salida, es simplemente un reactor con un agitador que homogeneiza la mezcla. Es esencialmente un tanque en el que se ha permitido que ocurra una reacción.

¿Qué son los biorreactores?

Las reacciones homogéneas se desarrollan usualmente en los cuatro primeros reactores; mientras que las heterogéneas suelen hacerlo en las tres últimas clases de reactores. Los biorreactores comúnmente tienen las siguientes características:

¿Cuáles son las dimensiones del bioreactor?

En la Fig.1 se muestran las dimen- bioreactor es en realidad de 24.7 litros. 12 ) a = 3534, 3 cm 3. Figura 1. Dimensiones del bioreactor comunes de transmitir o remover calor a un bioreactor. como la pared estacionaria.

¿Cuál es la ecuación de masa de un reactor batch?

Por lo tanto, la ecuación de balance de masa se reduce a: Así, en un reactor batch, el cambio de la concentración a lo largo del tiempo es simplemente el resultado de una reacción química. Por ejemplo, para una reacción de decaimiento de primer orden, r = -kC. Así, Las ventajas del reactor mienten con su flexibilidad.